In the meticulously controlled world of a cleanroom, the most significant threats are often the ones you can’t see. While operators focus on air filtration and surface sanitation, an invisible factor is constantly at play: humidity. Get it wrong, and you’re not just risking a failed batch; you’re creating a breeding ground for mold, bacteria, and other microbes that can lead to catastrophic product loss and regulatory failures.

The financial toll of a single contamination event can run into the millions. Yet, many facilities treat humidity as a secondary concern, a setting on the thermostat to be adjusted only when it becomes uncomfortable.

This guide is designed to change that. We’ll explore the science behind why humidity is the lifeblood of microbial growth and provide a clear framework for establishing precise, reliable control. You’ll learn not just how to manage humidity, but why specific levels are non-negotiable for product safety and operational excellence.

Foundation: The Science of Humidity and Microbes Made Simple

Before we can control the environment, we need to understand the forces at work. The relationship between air moisture and microscopic life is fundamental to cleanroom integrity.

What is Relative Humidity (RH), Really?

You see “RH” on every environmental monitor, but what does it actually mean? Think of air as a sponge. At any given temperature, that sponge has a maximum capacity for holding water vapor. Relative Humidity (RH) is simply a percentage that tells you how “full” that sponge is compared to its total capacity. So, 50% RH means the air is holding half the water vapor it possibly can at its current temperature. If you want a deeper dive into what humidity percentage means, it’s a fascinating topic.

How Humidity Fuels Microbial Growth

Microbes like mold and bacteria don’t drink water from the air directly. Instead, high relative humidity creates a microscopic, invisible film of water on every surface—a phenomenon known as “water activity.” This thin layer of moisture is the perfect nutrient-rich environment for a single spore to multiply into a thriving colony. When RH rises above 60%, water activity on surfaces increases dramatically, essentially opening a buffet for contaminants. This is a primary reason why effective clean room humidity control is so crucial.

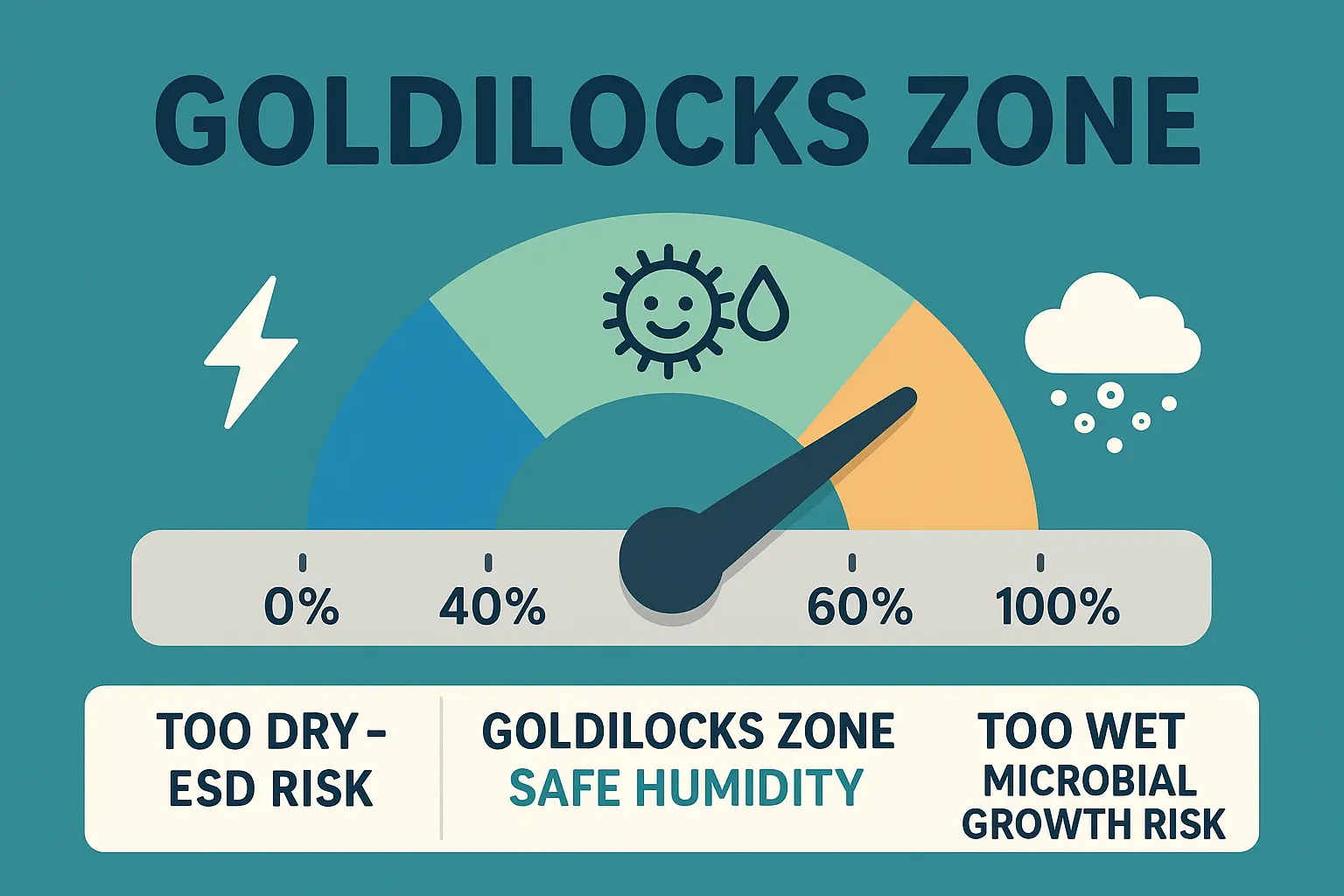

The “Goldilocks Zone”: Why 40-60% RH is the Sweet Spot

Managing cleanroom humidity isn’t just about preventing it from getting too high. It’s about maintaining a precise balance—a “Goldilocks Zone” that is typically between 40% and 60% RH.

- Above 60% RH: You invite microbial growth. Mold, fungi, and bacteria flourish. Metal surfaces can begin to corrode, and sensitive materials may degrade.

- Below 40% RH: The air becomes too dry, leading to a massive increase in electrostatic discharge (ESD). A single static shock can destroy sensitive electronic components or compromise pharmaceutical powders. Dry air also allows particulates to remain airborne for longer.

Staying within this zone is the first line of defense against a wide range of contamination risks.

Building: The Methods of Cleanroom Humidity Control

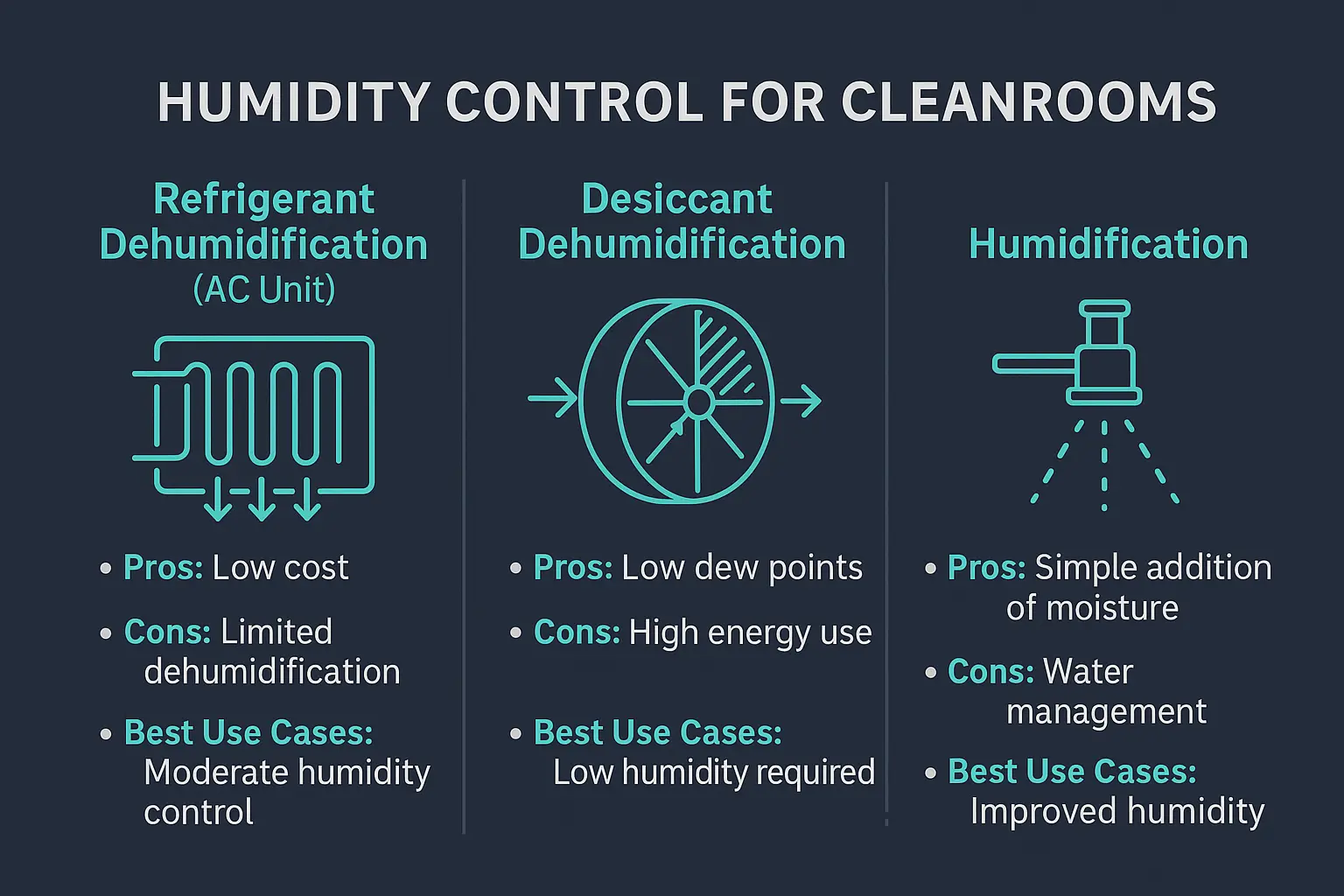

Achieving the Goldilocks Zone requires a deliberate strategy and the right technology. There are three primary methods facilities use to manage their environment, each with distinct advantages and applications.

| Method | How It Works | Pros | Cons | Best For |

|---|---|---|---|---|

| Refrigerant Dehumidification | Cools air below its dew point, causing moisture to condense and be drained away. It’s the same principle your standard air conditioner uses. | – Energy-efficient in moderate to high temperatures. – Cost-effective for removing large amounts of moisture. | – Less effective in cooler temperatures. – Can struggle to achieve very low RH levels (<40%). | General-purpose humidity reduction in environments that are not temperature-sensitive. |

| Desiccant Dehumidification | Air passes through a rotating wheel coated with a silica gel material (a desiccant) that absorbs moisture. A separate stream of heated air then “purges” the moisture from the wheel and vents it outside. | – Extremely effective at low temperatures and for achieving very low RH levels. – Provides precise humidity control. | – Higher initial investment and energy consumption compared to refrigerants. | Low-humidity applications like lithium-ion battery manufacturing, cold storage, and pharmaceutical processing. |

| Precision Humidification | Introduces microscopic water droplets into the air that evaporate instantly (a process called adiabatic humidification). This raises humidity without causing wetness or condensation on surfaces. | – Highly energy-efficient. – Provides precise, uniform humidity. – Non-wetting technology prevents conditions for mold or bacteria growth. | – Requires a source of compressed air and purified water for optimal performance. | Any cleanroom needing to raise or maintain humidity within the “Goldilocks Zone,” especially in electronics, pharma, and aerospace. |

Mastery: Application and Standards Across Industries

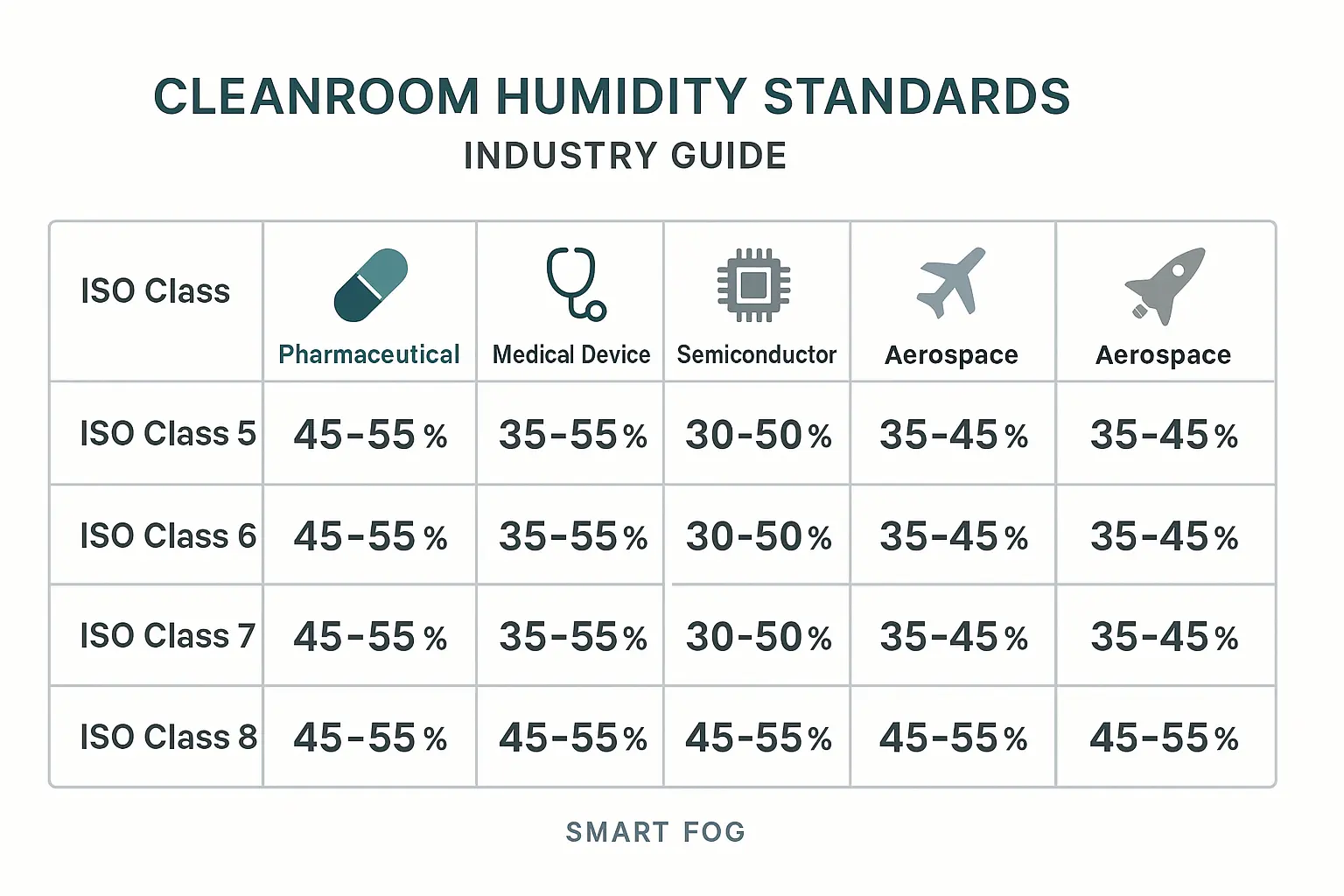

The ideal humidity target isn’t one-size-fits-all. It varies based on your cleanroom’s ISO class and the specific processes happening inside. Adhering to these standards is critical for regulatory compliance (e.g., FDA, CGMP) and consistent product quality.

A comprehensive humidity control system is more than just one piece of equipment; it’s an integrated network of sensors, controllers, and HVAC components working in unison.

| Industry / Application | ISO Class | Typical Temp Range (°C) | Typical RH Range (%) | Key Considerations |

|---|---|---|---|---|

| Semiconductor / Electronics | ISO 3-7 | 20-22°C | 40-55% | ESD prevention is paramount. Low humidity causes static buildup that can destroy microelectronics. |

| Pharmaceutical Manufacturing | ISO 5-8 | 20-21°C | 45-55% | Prevents microbial growth in sterile environments and ensures consistent powder flow and tablet compression. |

| Medical Device Assembly | ISO 7-8 | 20-22°C | 40-60% | Critical for material integrity (e.g., plastics, adhesives) and preventing static attraction of particulates. |

| Healthcare / Sterile Compounding | ISO 5-7 | 18-21°C | 40-60% | Air humidification in healthcare is vital for patient safety, infection control, and staff comfort. |

| Aerospace & Defense | ISO 7-8 | 20-24°C | 45-55% | Protects sensitive composites and coatings from moisture damage and prevents ESD during assembly of avionics. |

Action: Troubleshooting Common Humidity Problems

Even with a system in place, issues can arise. Here’s a quick checklist for diagnosing common problems:

- Problem: I’m seeing condensation on walls or equipment.

- Check: Your RH is likely spiking above 60-65%. Your dehumidification system may be undersized, or there’s an external source of moisture infiltration (e.g., a poorly sealed door).

- Problem: Staff are reporting static shocks and materials are sticking together.

- Check: Your RH has probably fallen below 40%. Your humidification system may need adjustment, or dry winter air is overwhelming its capacity. A dedicated humidifier for your clean room can provide the necessary control.

- Problem: My sensor readings are fluctuating wildly.

- Check: Ensure sensors are calibrated correctly and placed away from direct airflow from vents or doors. Inconsistent readings often point to poor air distribution or sensor malfunction.

- Problem: We passed an audit, but still see microbial growth.

- Check: Your control system might be maintaining the average RH correctly but allowing for brief, frequent spikes that are enough to promote growth. Also, look for “microclimates”—areas with poor airflow where moisture can collect. Another hidden culprit could be the humidification system itself. Conventional systems can harbor standing water, becoming a source of contamination.

This is where advanced humidification technology becomes a game-changer. Smart Fog systems utilize a patented process to create a self-evaporating dry fog. The 4.2-micron droplets evaporate completely in the air, raising humidity with absolute precision without ever wetting a single surface. With no moving parts, no standing water, and antibacterial components, the system itself cannot become a breeding ground for microbes, unlike traditional methods. This ensures you not only control humidity but also eliminate mold and other contaminants at the source.

Frequently Asked Questions (FAQ)

1. What’s the difference between relative and absolute humidity?Relative humidity is a percentage of how much moisture is in the air compared to the maximum it could hold at that temperature. Absolute humidity is the actual, measured mass of water vapor in a given volume of air. Cleanroom operators focus on RH because it’s the factor that determines water activity on surfaces and ESD risk.

2. Can I just use a consumer-grade humidifier or dehumidifier?Absolutely not. Consumer units lack the precision, reliability, and filtration necessary for a controlled environment. They often become sources of contamination themselves and cannot provide the uniform coverage required.

3. How often should I calibrate my humidity sensors?Most manufacturers recommend calibration every 6 to 12 months, but this can vary based on your industry’s regulatory requirements. Always follow your SOPs and the sensor manufacturer’s guidelines.

4. Does temperature affect my humidity control strategy?Yes, critically. Warm air can hold more moisture than cold air. This is why a unified relative humidity control strategy that manages both temperature and humidity is essential. A sudden drop in temperature can cause your RH to spike, potentially leading to condensation.

Take Control of Your Cleanroom Environment

Humidity is not a passive variable; it is an active and critical control point for preventing microbial contamination. By understanding the science, implementing the right technology, and adhering to industry standards, you can transform this invisible threat into your greatest asset for ensuring product quality, safety, and compliance.

Ready to learn more about how non-wetting humidification can protect your clean environment? Explore our complete solutions for clean rooms and see how precision control can make all the difference.