The Hidden Risk in Your Grow Room: Unstable Humidity

You’ve invested in lights, nutrients, automation, maybe even AI dashboards. But if your humidity swings just a few percent off target, your entire operation is at risk.

- Plants lose transpiration efficiency, uptake stalls, and growth slows.

- Mold thrives in high-RH microclimates—destroying weeks of careful work overnight.

- Low RH triggers static, pulling dust onto sensors and contaminating your canopy.

- Your HVAC fights to keep up, burning energy and still missing the mark.

Indoor agriculture humidity control isn’t a luxury. It’s the difference between consistent profits and costly, crop-crushing surprises.

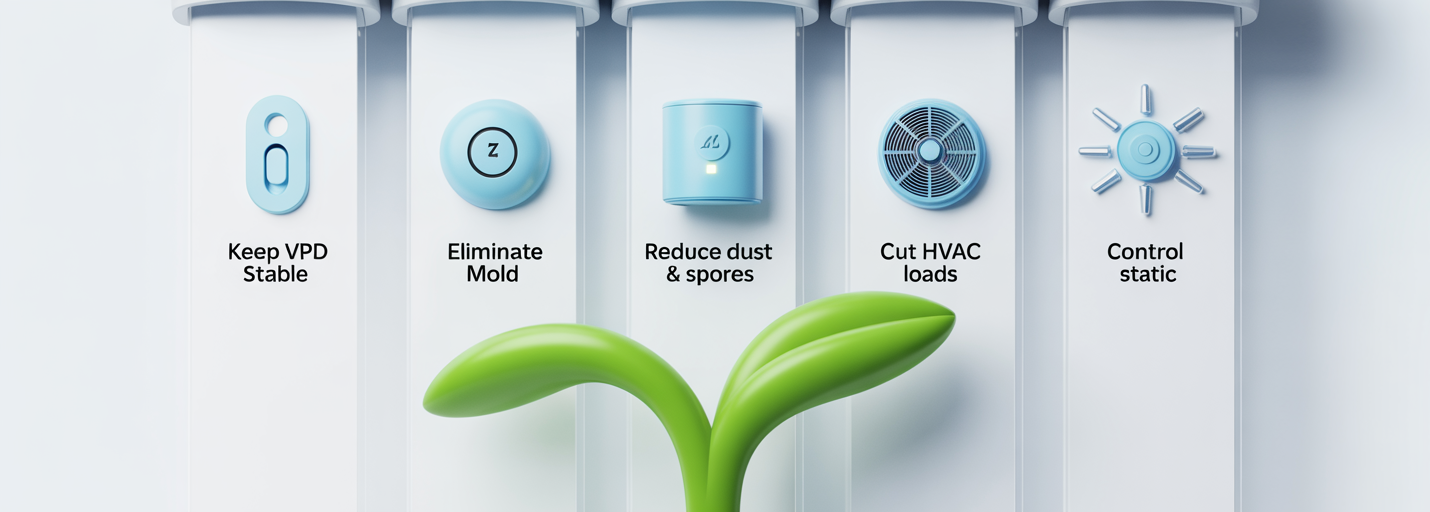

Smart Fog solves this. Using precision dry fog and natural air ionisation (the Lenard Effect), it stabilises RH within ±2%, actively reduces particles and pathogens, and neutralises static—without chemicals, heavy misting, or ozone.

In this guide, you’ll learn exactly how Smart Fog protects your crops, your margins, and your peace of mind.

1. Keep VPD Stable and Crops on Track

VPD (vapor pressure deficit) drives your plant’s ability to transpire—taking in nutrients, building structure, and resisting disease. If RH wavers, so does VPD.

Smart Fog delivers dry fog humidification that evaporates instantly, creating a uniform humidity profile across every rack and tier. That means:

- No oversaturation on lower leaves, no desiccation on top.

- Nutrients are drawn up consistently, reducing tip burn, bolting, and nutrient lockouts.

- Root zones stay balanced, speeding propagation and early growth stages.

Action takeaway:

By keeping VPD in the optimal range, you’ll see more uniform canopies, fewer stress responses, and tighter harvest cycles—improving turns per year and protecting your revenue.

2. Eliminate Mold and Pathogens Before They Start

Humidity is life or death for pathogens like powdery mildew, botrytis, and bacterial blight. Tiny RH spikes—caused by equipment cycles or door openings—create ideal microclimates for outbreaks.

Smart Fog’s system:

- Keeps RH within ±2%, stopping sudden conditions that let spores flourish.

- Produces negative air ions that bind to airborne mold spores and bacteria, making them heavy enough to drop out of circulation.

- Purifies the space continually, without harsh chemicals or separate fogging cycles.

Action takeaway:

Reduce or even eliminate the need for chemical treatments. Protect your “clean label” status. Avoid costly product downgrades or total crop loss from contamination events.

3. Achieve True Air Quality: Reduce Dust, Spores, and VOCs

Most growers rely on HEPA or MERV filters. But those only handle air passing through ducts—not what’s floating near your canopy or sticking to sensors.

Smart Fog’s ionisation clears the air in the grow zone itself:

- Bonds with PM2.5 and even sub-0.1 micron particles.

- Causes them to clump and drop out—keeping air clean around sensitive optics, lights, and plants.

- Reduces allergens and VOCs that can stress plants and workers alike.

Action takeaway:

Cleaner air isn’t just for compliance. It helps maintain optical efficiency in LED setups, ensures accurate sensor readings, and improves employee health.

4. Control Static and Protect Your Automation

Dry grow environments build static rapidly. That means:

- Dust and fibers cling to your lights, reducing PAR efficiency.

- Sensors misread data, sending false VPD or dosing commands.

- Static discharges silently damage controllers and disrupt sensitive automation.

Smart Fog eliminates this by maintaining stable RH and using ionisation to neutralise static at the air level—no mats or grounding bars required.

Action takeaway:

Protect your investment in climate tech and keep your automation delivering ROI, not chasing phantom alerts or unexpected downtime.

5. Cut HVAC Loads and Energy Costs

Traditional approaches try to maintain RH by ramping HVAC. That burns power—and still fails to control local microzones around canopy tops and dense racks.

Smart Fog reduces the load on your HVAC by stabilising humidity inside the room itself:

- Less air exchange needed, fewer swings in temp or RH.

- HVAC runs more efficiently, with less condensation on coils and fewer maintenance events.

- Cuts utility bills and helps meet sustainability targets.

Action takeaway:

A stable indoor atmosphere means you use less energy and spend less on maintenance—boosting profits on every harvest.

FAQs: What Growers Ask First

Q. Will it make my floors or plants wet?

No. Droplets are under 4.2 microns and evaporate before they reach surfaces.

Q. Is it safe around hydroponics, aeroponics, or fogponics?

Yes. It complements all CEA systems by dialling in ambient RH without interfering at the root zone.

Q. Does it add any chemicals or ozone?

No. Smart Fog is UL 2998 certified for zero ozone and uses only de-ionised water.

Q. How hard is it to install?

Most installs complete without downtime—emitters are mounted above canopy level, no trenching or heavy plumbing.

Q. Can it integrate into my existing environmental controls?

Yes. It connects to your BMS or standalone dashboards for live RH and air quality monitoring.

Conclusion: The Air Around Your Plants Is the Final Growing Medium

You track pH, EC, and PAR with precision. Your genetics are dialled. Your nutrients balanced.

But if your indoor agriculture humidity control fails—even for a day—everything else is at risk.

Smart Fog gives you:

- Stable VPD for vigorous, predictable growth.

- Reduced mold and pathogen load—often by 99% or more compared to passive setups.

- Cleaner air and static-neutral environments for automation that works.

- Lower HVAC loads and bigger energy savings.

In short: it protects your plants, your investment, and your peace of mind.