Dust is a way of life. At some point, it settles on nearly everything we own, and if not addressed, can collect quickly. If your home or workplace is near a busy road, an area of construction, or a location where the ground has been stripped, then dust can go from being a nuisance, to being an outright problem. Too much contact with dust can cause respiratory distress and irritation. It can also alter food safety and taste, as well as damage the surface of furniture and clothes.

In areas where dust is prevalent, a feather duster, or damp cloth, is often not enough to combat the number of particles. In cases such as these, dust suppression is your best option. Dust suppression is the practice of slowing or stopping the generation of excess dust. Appropriately applied dust suppression techniques can greatly improve the air quality and overall environment of living and workspaces where dust is problematic. There are multiple options for dust suppression and they can immediately make your living and working experience healthier and more comfortable.

Smart Fog Dust Suppression Systems

Effective dust suppression systems are necessary to meet EPA environmental air quality standards and protect workers’ health. Most methods of dust suppression involve expensive systems such as bag houses and electrostatic precipitators. New research and development has shown that humidity addition systems using Under 10-micron water droplets attract and suppress PM 10 and smaller dust particles.

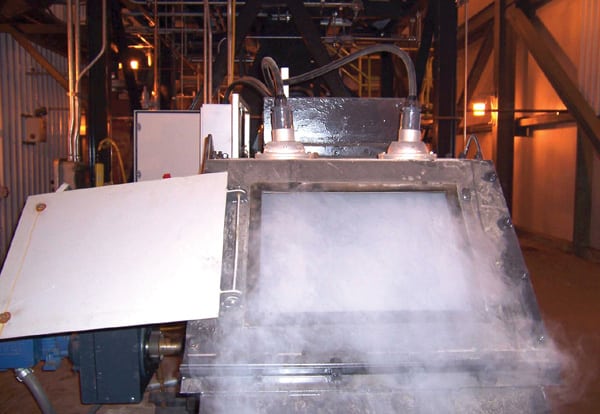

Smart Fog MS100 Fogger dust suppression systems have been essential in the USA in helping companies meet the EPA standards for dust suppression.

The Smart Fog MS100 Fogger is the solution for optimal dust suppression.

How Our Dust Suppression Equipment Works

Smart Fog’s Fogger uses supersonic compressed air to blast water into droplets 4.2 micron

(Defined as Dry Fog) in diameter. These tiny water droplets absorb even the smallest dust particles in the air, yet fall to the ground without wetness. Particularly suited for dusty environments, the dry fog dust suppression system nozzle has a large 0.1″ orifice, which won’t clog like pinhole foggers do.

Benefits

- Our dust suppression systems help Helps you meet environmental standards: Custom installations can reduce dust to required levels, for environmental and worker safety standards.

- Smallest droplets give maximum dust control.

- Inexpensive to operate: Low water and electricity consumption save running costs.

- Low Maintenance: The Smart Fog MS100 Fogger System’s large 0.1″ orifice prevents clogging, even with hard water. With no moving parts in the fogger, you will have years of reliable low-maintenance operation.

Proven Results

Smart Fog’s field experience and dedicated service make it the only choice for the most reliable and effective dust suppression systems.

Academic Research

Research literature has long recognized that small droplet size is the key to dust suppression system. The following explanation comes from work at the Colorado School of Mines:

When water droplets that are sprayed to control coal dust are too large, the dust particles flow around the droplets, and thus are not absorbed-but water droplets too small simply evaporated. So CSM is looking into theories governing formation of clouds to improve existing water spray technology.

Experience gained over the years with water sprays has established the following facts: (1) For a given spray nozzle, the collection efficiency for small dust particles increases as the pressure increases, and (2) at a given pressure, the efficiency increases as the nozzle design is changed so as to produce smaller droplets. The conclusion is clear-cut; the smaller droplets are more effective in knocking small dust particles out of the air. The reason for this is not hard to see.

Consider a water droplet about to impinge on a dust particle, or what is aerodynamically equivalent, a dust particle about to impinge on a water droplet, as shown in the drawing. If the droplet diameter is much greater than the dust particle, the dust particle simply follows the airstream lines around the droplet, and little or no contact occurs. In fact, it is difficult to impact micron-size particles on anything, which is why inertial separators do not work well at these sizes.

If, on the other hand, the water droplet is of a size that is comparable to that of the dust particle, contact occurs as the dust particle tries to follow the streamlines. Thus the probability of impaction increases as the size of the water spray droplets decreases.

The Best Systems for Dust Suppression

While humidifiers are commonly associated with creating elevated levels of air moisture for food ripening and other processes, these machines are also important in industrial dust suppression. Sensitive equipment is easily interfered with by accumulated debris, and particles which swirl through an enclosed space can also prove a health hazard to workers. Humidifiers suppress these particles by trapping them in water droplets, so that they become heavier and sink down, leaving cleaner air space.

The best systems for dust suppression are capable of producing water droplets that are minute in size. These tiny droplets disperse evenly throughout an enclosed space, so that they do not adhere to each other and condense into wet patches. The accumulation of spots of damp can lead to the growth of mold or to structural problems, thus it is wise to invest in a recent system which avoids such problems. A fog system which is effective at suppressing dust may be ordered through www.smartfog.com.

Clean Environment With Smart Fog Dust Suppression

Smart Fog humidifiers offer 100% dust suppression. With our systems, you can safeguard and protect workers so that they do not breathe large amounts of dust for long periods of time. Both the Occupational Safety and Health Administration (OSHA) and the Environmental Protection Agency (EPA) have established guidelines so that business owners can comply with these standards. Simple breathing masks do not always eliminate enough dust particles to keep employees safe and healthy.

How our smart fog dust suppression systems work

At Smart Fog, we have created a proven method of dust suppression. The water droplets produced by our humidifiers are the smallest in the industry. They trap dust particles so that cannot travel through the air. Our tiny droplets are capable of catching all sizes of dust particles. Our humidifiers produce many more droplets than most systems because they are so small, so there are far more droplets in the air to catch the dust particles. Our systems have been proven to provide 100% dust suppression.

Our products offer long-lasting dust suppression

Our humidification equipment keeps dust out of the air. We use the best materials to make our humidifiers right here in the USA.

Our Clients

Trusted by industry leaders:

And Many More…