You’ve checked the seals, verified the airlocks, and reviewed every protocol, yet a phantom threat persists. Unexplained particle counts, random static shocks, and even microscopic microbial growth are jeopardizing your yields and compromising your controlled environment. You’ve looked everywhere, but have you looked up? The culprit might be hiding in plain sight, disguised as a solution: your humidification system.

Many cleanrooms rely on humidity control, but traditional systems often introduce a problem as dangerous as the one they solve—unwanted moisture. This “wet” humidity can become a breeding ground for contamination and a catalyst for product failure. It’s time to shed light on this unseen threat and explore a smarter, drier alternative.

The Delicate Balance: Why Humidity is a Cleanroom’s Best Friend (and Worst Enemy)

In a cleanroom, air isn’t just air; it’s a precision-engineered tool. Maintaining the right level of relative humidity (RH) is critical for protecting sensitive products and processes. Get it wrong, and the consequences can be costly.

1. Taming Electrostatic Discharge (ESD): In an environment that’s too dry, static electricity builds up on surfaces, equipment, and even personnel. A sudden discharge can fry a semiconductor or damage sensitive electronics. Many facility managers wonder, why does low humidity cause static electricity? It’s because moisture in the air creates a conductive path that allows static charges to dissipate safely. Optimal humidity acts as a natural safeguard against invisible, product-killing sparks.

2. Suppressing Airborne Particles: Proper humidity makes the air slightly “heavier,” causing dust, microbes, and other contaminants to settle out of the air more quickly. This reduces the chance of particles landing on a critical surface during manufacturing or packaging.

3. Preventing Microbial Growth: This is where the balance becomes tricky. While some humidity is good, too much—especially in the form of condensation or wet spots—creates the perfect environment for mold, bacteria, and fungi to thrive.

The Problem with “Wet” Humidification: When Good Intentions Go Wrong

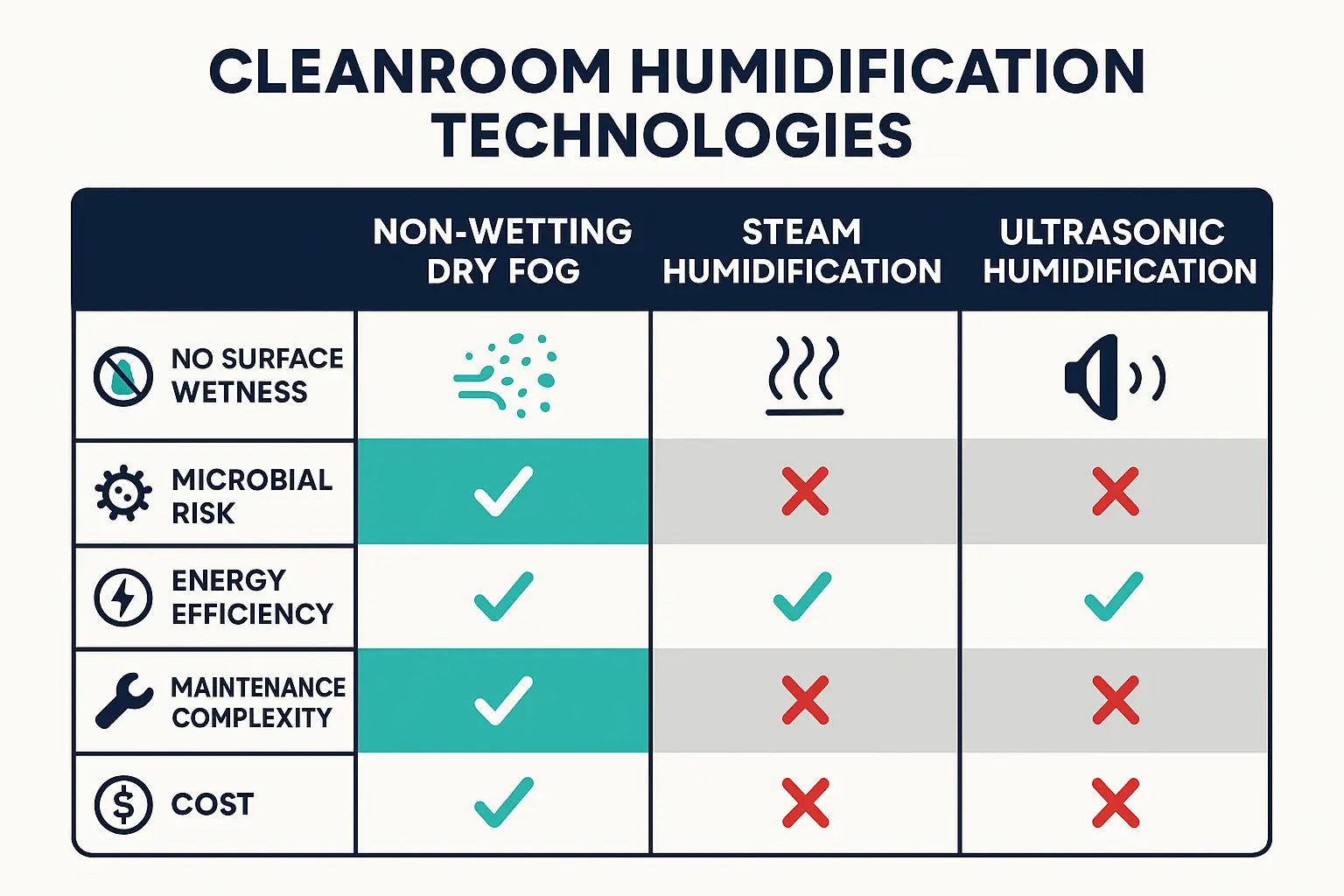

To achieve the right RH levels, many facilities turn to traditional humidification methods like steam canisters or ultrasonic systems. While functional, these technologies carry inherent risks for a sterile environment.

- Steam Humidification: Boiling water to create steam is effective but incredibly energy-intensive. It also introduces high temperatures into the HVAC system, forcing your cooling systems to work overtime and driving up operational costs. A detailed steam humidification comparison reveals the significant energy trade-offs.

- Ultrasonic Humidifiers: These systems use vibrating diaphragms to create a cool mist. However, they are notorious for producing larger water droplets that don’t evaporate fully. This leads to damp surfaces, condensation, and “white dust”—mineral deposits left behind when the water evaporates, adding a new source of contamination.

The common denominator of these older methods is the risk of wetness. Standing water in a duct or condensation on a surface is more than just a nuisance; it’s a critical failure point that invites microbial contamination into the heart of your controlled environment.

The “Aha” Moment: Unpacking the Science of Non-Wetting Humidification

What if you could get all the benefits of humidity without a single drop of unwanted wetness? That’s the revolutionary promise of non-wetting humidification technology.

The secret isn’t magic; it’s physics.

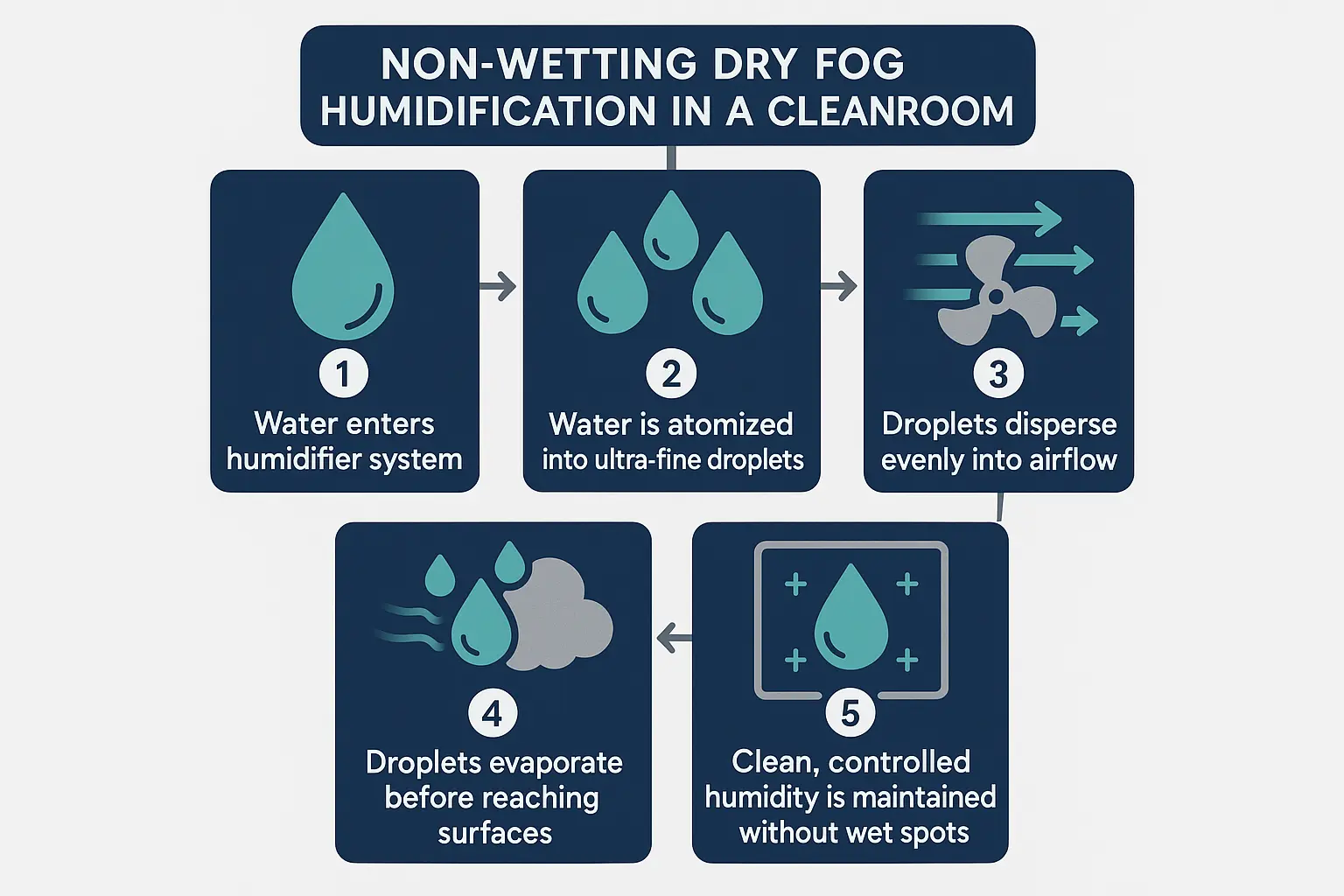

Imagine trying to wet a surface with a can of aerosol hairspray. You can spray it all day, but the surface never gets damp. Why? The particles are so microscopic that they are absorbed by the air before they have a chance to land and combine.

Non-wetting systems use a similar principle. By atomizing water into droplets smaller than 5 microns (for reference, a human hair is about 70 microns thick), they create a true dry fog. These tiny droplets have an enormous amount of surface area relative to their volume, allowing them to be absorbed into the air almost instantly. The result is a precise increase in humidity without condensation, wet spots, or drips. This method of non-wetting humidification is a game-changer for sterile environments.

This process is also a form of evaporative cooling. As the water droplets evaporate, they draw heat from the air, a process that makes it an efficient adiabatic humidifier. This provides an added benefit: reducing the load on your cooling systems and lowering energy bills even further.

Choosing the Right Shield for Your Cleanroom

Switching to a non-wetting humidification system isn’t just an equipment upgrade; it’s a strategic move to de-risk your entire operation. By eliminating the root cause of many contamination issues—uncontrolled moisture—you can achieve more consistent yields, protect sensitive products, and create a safer, more efficient cleanroom.

When evaluating systems, it’s crucial to understand how different technologies stack up. Factors like energy consumption, maintenance needs, and, most importantly, the risk of surface wetting should be at the top of your checklist. The right system for your clean room humidity needs will depend on your specific ISO class and application.

Frequently Asked Questions About Cleanroom Humidification

What is the ideal humidity level for a cleanroom?

This depends on the application, but a common range is 30% to 50% RH. For electronics and semiconductor manufacturing, 40-50% RH is often targeted to mitigate ESD. In pharmaceutical applications, the range might differ to protect product integrity. Always refer to your industry-specific standards.

Can a humidifier introduce contaminants?

Yes. Traditional ultrasonic humidifiers that use tap water can disperse minerals and microorganisms into the air. Steam systems are sterile, but their high energy use is a drawback. Non-wetting dry fog systems that use deionized or reverse osmosis water are the safest option, as they produce a pure vapor with no additives.

What are the main benefits of non-wetting vs. traditional humidifiers?

The top three benefits are:

- Contamination Control: No wet surfaces means no breeding ground for mold and bacteria.

- Energy Efficiency: Dry fog systems use a fraction of the energy consumed by steam-based systems. There are many cool mist humidifier benefits that contribute to lower operational costs.

- Product Safety: Precise humidity control prevents ESD damage without the risk of water damage.

The Path to a Smarter, Safer Cleanroom

The hidden dangers of “wet” humidity are real, but they are not unavoidable. By understanding the science behind non-wetting technology, you can make an informed decision to protect your cleanroom from the ground up. Moving beyond outdated methods is the first step toward a more reliable, efficient, and contamination-free environment.

Ready to take control of your atmosphere? Learn more about advanced solutions for clean room humidity control and discover how the right technology can become your facility’s most powerful shield.