Your HVAC is Working Overtime — And It’s Probably Still Missing the Mark

Walk into almost any indoor agriculture facility and you’ll feel it: the cool, conditioned air blasting through ducts overhead. The slight whoosh around door seals. The ever-present hum of compressors and fans in the background.

Growers pride themselves on tight environmental control. And rightly so — if you let your temperature or humidity drift too far, you pay for it in lost yields, disease, and compliance headaches. But here’s the irony: in most operations, all that money poured into HVAC isn’t actually solving the problem — it’s chasing it.

What’s worse, the more your system struggles, the more energy you burn. And even then, you might still find:

- RH that swings by 5-8% every HVAC cycle.

- Microzones near lights or racks that never hit the target range.

- Condensation forming in ductwork or on cold surfaces — perfect spots for biofilms to grow.

You’re paying top dollar to maintain instability. But it doesn’t have to be that way.

Why HVAC-Only Humidity Control Falls Short

Most indoor farms rely on traditional HVAC to handle both temperature and humidity. It’s convenient — until you look at how that actually works.

- Your system cools air to remove moisture (condensation on coils).

- It might then reheat air to bring temps back up, after over-cooling.

- Humidistats kick on and off based on broad thresholds, creating swings.

That means every time your system cycles, it over-corrects. You get repeated minor RH crashes, followed by humidity drifting back up. Plants (and pathogens) notice these swings long before you do.

Plus, this approach wastes energy two ways:

- Over-cooling just to dehumidify burns excess electricity.

- Reheating air after over-cooling multiplies costs.

It’s a brute force solution to what should be a fine-tuned problem.

The Hidden Moisture Problem in Closed Environments

CEA environments — especially vertical farms — recycle air to keep CO2 levels stable and reduce energy losses. But with that comes another issue: moisture accumulates.

Plants transpire water vapor constantly. So do irrigation mist cycles, small leaks, even worker respiration. In tight spaces under heavy LED loads, that moisture doesn’t dissipate evenly. You can have RH of 80% at canopy level and 50% by the floor. Your HVAC sensor might show a comfortable 65% average — completely missing the hot spots where mold starts or plants stress.

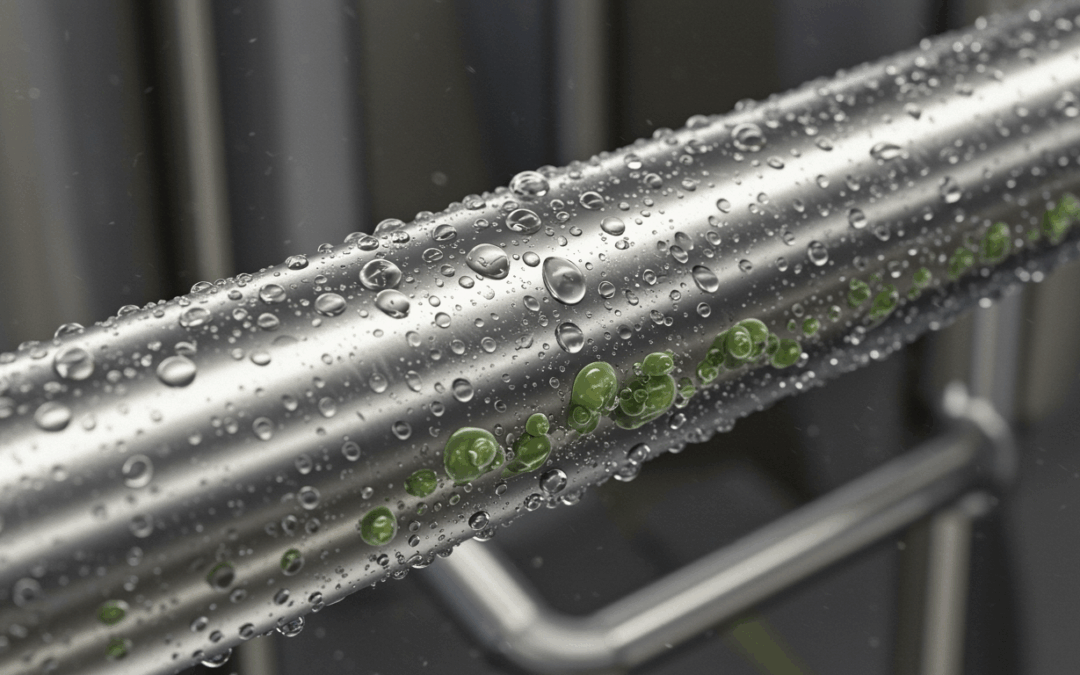

This imbalance causes local condensation. On cool pipes. Under trays. Inside wall cavities. Places you can’t see but that microbes find in a heartbeat.

Static and Particle Buildup: The Double-Edged Energy Drain

Dry swings don’t just risk your crops — they change the entire electrical load of your facility.

- Static charges build in low RH zones. They attract dust and fibers, which insulate coils and reduce heat exchange efficiency.

- Fine particles recirculate endlessly, landing on LED optics. Even a light film can cut intensity, meaning you run lights harder (or longer) for the same PPFD.

In other words: unstable air makes your gear work harder and less efficiently. You pay more on your bills and replace expensive infrastructure sooner.

How

Smart Fog Cuts Energy Costs (While Actually Improving Stability)

Smart Fog doesn’t try to use brute force. Instead of supercooling air to wring out moisture and then reheating it, it maintains a balanced environment with ultra-precise RH control — often holding within ±2% of setpoint.

Here’s what that means for your energy spend:

- HVAC cycles less aggressively. Because humidity is stabilized directly in the room, your main system doesn’t have to over-process air just to catch up.

- Less reheating. Maintaining RH without driving temps down means you skip the costly warm-up phase.

- Better coil efficiency. Reduced static and particles keep heat exchange surfaces clean, improving SEER ratings and lowering runtime.

- Optimized LED performance. With less dust and static pulling particles onto optics, your lights deliver more photons for the same watts.

Smart Fog’s tiny droplets evaporate instantly. There’s no surface wetting, no added load on your drains, and no risk of micro-pools that lead to mold or bacterial growth.

The Compliance and Maintenance Bonus: Fewer Surprises at Audit Time

Many indoor ag operators run into surprise issues at inspection — not from their crops directly, but from the HVAC side.

- Excess condensation in ductwork harbors microbial biofilms, flagged under GMP or HACCP protocols.

- Fluctuating RH levels raise questions on process logs, triggering corrective actions or tighter scrutiny.

- Overworked systems need more frequent servicing, with sudden breakdowns that halt climate control entirely.

Because Smart Fog stabilizes the environment right in the grow zone, it takes pressure off your big systems. That means longer intervals between major maintenance events, fewer urgent service calls, and less last-minute panic cleaning before an auditor walks through.

Why Growers Report Paying Less (and Stressing Less)

Operators who add Smart Fog systems often notice something surprising: their electric bills go down, even while their air gets more stable.

It makes sense. Instead of asking HVAC to constantly battle the moisture plants give off — over and over, day after day — Smart Fog levels out the playing field. Your HVAC still handles big temperature shifts, but no longer has to over-cool and over-reheat to chase humidity.

Plus, because air is cleaner and static is neutralized:

- LED lifespan extends.

- Sensors stay accurate longer.

- Downtime for cleaning drops dramatically.

That’s all real money, real hours, and real headaches saved.

FAQs: Your Practical Concerns Answered

Q. Will Smart Fog replace my HVAC?

No. It works alongside your HVAC, taking over the fine-grain humidity control and air cleaning your ducts can’t handle.

Q. Does this mean I can downsize future HVAC installs?

In many cases, yes. By handling humidity at the source, you may not need oversized systems just to keep RH in check.

Q. Will it leave moisture on my plants or equipment?

Not at all. Droplets are under 4.2 microns and evaporate in the air — no pooling, no condensation.

Q. Is it complicated to run?

It’s simpler than most grow automation gear. Once your parameters are dialed in, it runs automatically, with minimal oversight.

Conclusion: Stop Paying More Just to Risk More

It’s ironic: most indoor farms pour thousands into massive HVAC builds, then pay hefty monthly bills, only to see unstable environments that sabotage yields anyway.

Smart Fog flips that script. By managing humidity directly where your plants live — and purifying the air with natural negative ions — it cuts the workload for your existing systems. You use less energy, spend less on maintenance, and get healthier plants that finish faster and cleaner.

If your utility bills make your stomach drop every month (or if your HVAC still can’t stop mold from popping up), it might be time to rethink your approach.