Imagine this: a multi-million dollar batch of microchips, months in the making, is rendered useless in the final stage of production. The culprit isn’t a machine malfunction or a material defect. It’s an invisible surge of static electricity, a microscopic arc of energy that jumps from a surface to a component, frying it instantly. The root cause? The air was just a little too dry.

This scenario, and others like it—from microbial blooms on sterile equipment to inconsistent coatings on medical devices—is why ISO 14644-4 exists. It’s not just another line item on a compliance checklist; it’s a critical framework for protecting your products, your processes, and your bottom line.

But let’s be honest, diving into ISO standards can feel like trying to read a legal document. It’s dense, technical, and can leave you with more questions than answers.

That’s where this guide comes in. We’re going to translate the standard into a practical roadmap, transforming the complex into the clear. Think of this as a conversation with a friend who has spent years mastering the art and science of cleanroom environments. Together, we’ll explore not just what the rules are, but why they matter and how to build a system that makes compliance second nature.

What is ISO 14644-4, and Why Should You Care?

At its core, ISO 14644-4 is part of a larger family of standards focused on cleanrooms and their associated controlled environments. While other parts deal with particle counts and testing procedures, Part 4 zeroes in on the design, construction, and start-up of these facilities. A huge piece of that puzzle is managing the invisible factors in the air—namely, temperature and humidity.

Ignoring these can lead to three catastrophic, process-killing problems:

- Electrostatic Discharge (ESD): When air is too dry, static electricity builds up on surfaces, people, and equipment. For industries like electronics manufacturing, a single ESD event can destroy sensitive components, leading to crippling yield loss. Proper humidity makes the air slightly more conductive, allowing static charges to safely dissipate before they can cause damage. Understanding how to manage humidity and electronics is not just best practice; it’s a financial necessity.

- Microbial Growth: Conversely, when the air is too damp, it becomes a breeding ground for mold, bacteria, and other microorganisms. In pharmaceutical, biotech, and medical device manufacturing, this poses an unacceptable contamination risk that can endanger patients and trigger costly recalls.

- Product & Process Integrity: Many manufacturing processes rely on precise environmental conditions. For example, powders may not flow correctly, coatings can fail to adhere, and hydroscopic materials (which absorb moisture from the air) can swell and change dimension, compromising quality.

The Goldilocks Zone: Decoding Humidity Requirements

The key to compliance isn’t just adding or removing moisture; it’s about maintaining a precise and stable balance. This balance is measured in relative humidity (RH), which is the amount of water vapor in the air compared to the maximum amount it could hold at that temperature.

Most cleanrooms operate within a general range of 30% to 60% RH, but the ideal target depends heavily on your specific application. The goal is to find the “Goldilocks zone”—not too dry, not too wet, but just right for your process.

Foundation section explaining key terminology and principles of humidity control

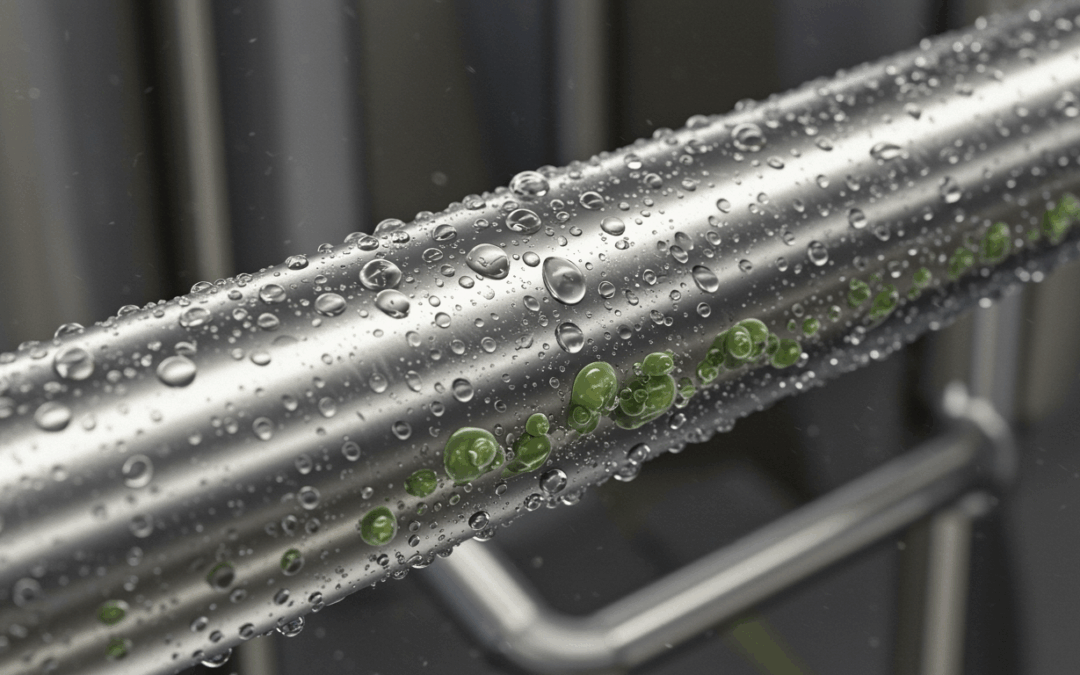

This visual clarifies how relative humidity is measured and controlled in manufacturing cleanrooms, showing the connection between temperature and moisture essential for ISO 14644-4 compliance.

This visual clarifies how relative humidity is measured and controlled in manufacturing cleanrooms, showing the connection between temperature and moisture essential for ISO 14644-4 compliance.

Different industries have vastly different needs. An electronics facility might operate on the drier side (30-40% RH) to prioritize ESD protection, while a pharmaceutical industry cleanroom may target a higher range (45-55% RH) to prevent microbial growth without introducing other issues. The standard provides the framework, but your process defines the target.

From Standard to System: Engineering Your Compliant Cleanroom

Achieving consistent humidity control doesn’t happen by accident. It must be engineered into the heart of your facility: the Heating, Ventilation, and Air Conditioning (HVAC) system. Think of your HVAC system as the lungs of your cleanroom—it’s responsible for breathing in, filtering, conditioning, and circulating every cubic foot of air.

A properly designed system for clean room humidity control integrates several key components:

- Chillers/Heaters: To bring the air to the correct temperature.

- Dehumidifiers: To remove excess moisture, often by cooling the air below its dew point.

- Humidifiers: To add precise amounts of water vapor back into the air to reach the target RH.

- Sensors & Controls: The “brain” of the system, constantly monitoring conditions and making micro-adjustments to maintain stability.

This is where the right technology makes all the difference. Traditional humidification methods can sometimes create more problems than they solve, such as condensation, wet spots, and high energy consumption. Modern solutions, however, are designed to integrate seamlessly, delivering moisture as a dry fog that evaporates instantly, ensuring uniform humidity without wetting any surfaces. This level of commercial hvac humidity control is essential for meeting the strict demands of ISO 14644-4.

Section on engineering and system design explaining equipment and monitoring

This diagram breaks down the HVAC process used to precisely control humidity levels in a clean manufacturing cleanroom, directly linking each system component to its role in compliance with ISO 14644-4.

This diagram breaks down the HVAC process used to precisely control humidity levels in a clean manufacturing cleanroom, directly linking each system component to its role in compliance with ISO 14644-4.

A Quick Guide to Cleanroom Humidity by Class & Industry

While every facility is unique, certain patterns emerge across different cleanroom classifications and industries. This chart provides a general reference to help you benchmark your own requirements.

Action section focused on troubleshooting and retention of key standard ranges

A quick-reference visual guide to ISO 14644-4 humidity requirements across cleanroom classes and manufacturing sectors, helping readers remember critical ranges and their relevance.

A quick-reference visual guide to ISO 14644-4 humidity requirements across cleanroom classes and manufacturing sectors, helping readers remember critical ranges and their relevance.

Your ISO 14644-4 Compliance FAQ

What’s the difference between ISO 14644-4 and other parts of the standard?

Think of it this way: Part 1 defines the classes of air cleanliness by particle count. Part 2 specifies the monitoring requirements to prove performance. Part 4 provides guidance on the design and construction needed to achieve the goals set out in the other parts. They all work together.

How often should I monitor humidity levels?

ISO 14644-2 recommends continuous monitoring. A robust Building Management System (BMS) with sensors that record data 24/7 is the industry best practice. This allows you to not only prove compliance but also identify trends and prevent deviations before they become problems.

Can I just use a standard commercial humidifier in my cleanroom?

It’s highly discouraged. Cleanrooms require specialized equipment. A professional cleanroom humidifier is designed to be non-contaminating, use purified water, produce a non-wetting fog, and integrate precisely with your facility’s control systems. Standard humidifiers can introduce minerals, microorganisms, and moisture that can compromise the entire environment.

What happens if my cleanroom humidity falls out of specification?

If monitoring shows a deviation, your facility’s standard operating procedures (SOPs) should kick in. This typically involves investigating the cause (e.g., HVAC malfunction, a door left open), documenting the deviation, assessing the impact on any products manufactured during that time, and taking corrective action to bring the environment back into compliance.

The Path Forward: Achieving Effortless Compliance

Mastering humidity control isn’t about chasing a number on a sensor read-out. It’s about creating an environment so stable and reliable that compliance becomes an outcome, not a daily struggle. By understanding the core principles of ISO 14644-4 and investing in a system designed for precision, you can eliminate environmental variables and focus on what you do best: innovation and production.

Your cleanroom is a high-performance machine. Ensuring every component works in harmony—especially the invisible atmosphere within it—is the key to unlocking its full potential. When you turn a compliance requirement into a competitive advantage, you’re not just meeting a standard; you’re setting a new one.