It’s Not Just Your Roots: Why Your Air Determines Your Harvest

You’ve probably heard it said that “healthy roots equal healthy fruits.” That’s true. But there’s a silent partner in every successful harvest that most growers overlook: the air.

Walk through most indoor farms — whether it’s a vertical lettuce facility or a cannabis grow — and you’ll see beautifully organized racks, perfectly tuned nutrient systems, and LED rigs carefully calibrated to hit precise PPFD levels.

Yet ask the same grower how stable their air quality really is, and you’ll often get a shrug. “We’ve got filters. The HVAC’s dialed.” End of story.

Here’s the uncomfortable truth: ignoring air quality is costing you yield. Not just through catastrophic events like mold outbreaks, but through small, daily losses that add up to lower biomass, slower turns, and uneven product quality.

Let’s pull back the curtain on why air is just as much a growing medium as your water or substrate — and how controlling it can put serious money back on your bottom line.

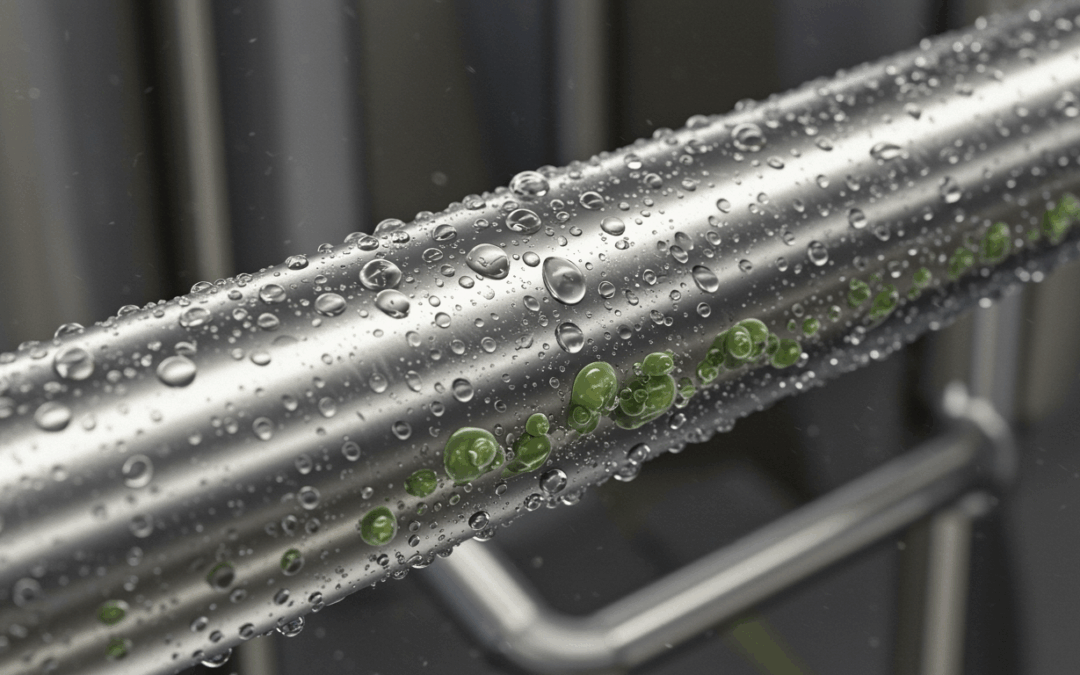

Hidden Enemy #1: Airborne Particles That Stress Your Crop

Take a look at the air under your canopy. Even if it looks clean, it’s not. Every cubic meter holds thousands of tiny contaminants: bits of grow medium, microscopic fibers from packaging, fragments of plant matter from previous harvests.

- Tiny particles settle on stomata, clogging them and interfering with gas exchange.

Plants literally struggle to breathe — reducing transpiration and slowing nutrient uptake. - Fine dust reduces light penetration.

Even a thin layer on leaves cuts down the PAR your plants can use. - Particles act as carriers for pathogens.

They pick up fungal spores and bacteria, delivering them straight to moist leaf surfaces.

So while your HVAC might filter out larger contaminants, it often can’t touch the small stuff. And standard air turnover rates (ACH) in grow facilities aren’t nearly high enough to pull particles out before they cause problems.

Result: Your plants quietly underperform, day after day, without any dramatic “disease event” to tip you off.

Hidden Enemy #2: The Wrong Kind of Air Charge

In dry environments — which most indoor farms unintentionally create — air becomes statically charged. That’s more than an operator getting a small zap. It’s an active force that pulls particles right onto plant surfaces and sensitive sensors.

- Dust, spores, and even heavy metals from nearby machinery become electrostatically attracted to leaves.

- Sensors that rely on optical clarity — like PAR meters or vision systems — get a film of debris that skews readings.

- Electronic controllers suffer long-term wear from tiny static discharges, shortening lifespan or causing erratic data.

Your HVAC can’t solve static. In fact, most filtration setups make it worse by drying the air further. Grounding mats under benches help operators, but do little for the airborne charges swirling around the canopy.

Hidden Enemy #3: Microbes That Never Get Filtered

Let’s be brutally honest: most grow operations rely on their HVAC or separate duct filters to keep pathogens at bay. But microbes — especially bacteria and fungal spores — are often so tiny they slip right through filters. Or worse, they live happily on the coils and drip pans inside your HVAC itself, where humidity fluctuates and biofilms thrive.

Every time your fans kick on, these microbes get blown straight back into your grow zone. Even high-grade HEPA filters only capture what passes through them, not what’s already in the air between your plants.

Without an active way to neutralize microbes inside the grow environment, you’re gambling on luck. And in this industry, luck is never a reliable strategy.

How Smart Fog Changes the Entire Air Ecosystem

Smart Fog approaches air not as something to move around or just keep cool, but as a vital growing medium that needs the same care as your nutrient solution.

It uses two core tools:

- Ultra-fine dry fog that stabilizes RH precisely where it needs to be, so your plants stay in optimal VPD without pooling or condensation.

- Negative air ions generated via the Lenard Effect, which bond to particles, dust, spores, even volatile organic compounds (VOCs), making them heavy enough to drop harmlessly out of the breathing zone.

Because these ions are created right inside the grow environment, they go everywhere air does — in between dense foliage, under benches, even around tightly packed sensors. That’s control no duct-mounted filter can offer.

The Economic Impact: It’s Bigger Than You Think

When we talk about “air quality problems,” most growers only imagine catastrophic crop losses. But the far more common scenario is steady underperformance:

- Plants that take an extra week or two to finish.

- Biomass that’s 5-10% lower than genetic potential.

- Batches that fail microbial tests, requiring remediation or outright disposal.

- Sensors that drift over time, causing slight overfeeding or underfeeding that compounds across cycles.

Add that up over a year, and it’s not a small issue. For many operations, simply stabilizing RH and actively scrubbing the air of particles and static can improve yields by multiple percentage points per cycle — with downstream savings on HVAC energy and fewer callbacks to fix tech glitches.

What About “Normal” Humidifiers and Air Filters?

If you’re thinking, “I already have humidity control and air filtration,” you’re not alone. Nearly every modern facility does. But here’s the problem:

- Standard humidifiers often produce droplets large enough to settle on leaves or equipment. That creates micro-wet zones — perfect for mold.

- They also lack fine-grain control, swinging RH by 5% or more. That stresses plants and drives static back up.

- Traditional filters only work on air that passes through ducts, not on the millions of particles floating directly around your canopy.

Smart Fog’s system is designed to solve precisely these shortcomings. It creates a homogenous microclimate with RH fluctuations held to within ±2% — while the air itself becomes actively “self-cleaning” thanks to widespread ion coverage.

The Human Factor: Better Air Is Better for People, Too

We’ve focused mostly on your plants and profits, but there’s a huge secondary benefit: your staff.

Workers in facilities with stable humidity and fewer airborne particles report:

- Less respiratory irritation

- Fewer allergy flare-ups

- Reduced skin dryness and static shocks while handling equipment

Happy workers stay longer, are more careful with your sensitive systems, and create fewer compliance headaches. It’s another subtle way that investing in air quality pays for itself.

FAQs: Clearing Up the Final Doubts

Q. Is Smart Fog safe around edible crops or organic certification?

Absolutely. It uses only de-ionized water and creates zero ozone or chemical residues. Many growers maintain USDA Organic and GACP certifications with it in place.

Q. Will it replace my existing HVAC?

No — it complements your HVAC by reducing how hard it needs to work. Most facilities see lower energy costs and longer equipment life.

Q. How hard is it to maintain?

Smart Fog systems have no filters to replace and no messy tanks to scrub. Regular checks are simple, usually handled alongside normal facility rounds.

Conclusion: The Air in Your Grow Is Either Helping You — Or Hurting You

Most indoor farms get so focused on the visible: the lush green canopies, the sparkling LEDs, the perfectly dialed drip emitters. But all of that rests on something invisible: the quality of your air.

When you treat air as just something to cool or circulate, you’re leaving huge profits on the table. But when you treat it like the final growing medium — controlling RH, stripping out particles and spores, neutralizing static — everything else clicks into place.

More uniform growth. Faster turns. Less disease. Happier workers. Lower bills.

Smart Fog gives you that. It’s why leading leafy greens operations, cannabis producers, and vertical farms trust it not just for show, but because it pays them back every cycle.