Humidity Control in Manufacturing Facilities: Preventing Static, Mold & Downtime with 24/7 Smart Fog Systems

Imagine a tiny static spark halting an entire assembly line, or an unseen patch of mold contaminating a whole batch of product. In U.S. manufacturing facilities, seemingly minor factors like humidity can have major impacts on operations. That’s why humidity control in manufacturing facilities is so critical. Maintaining optimal moisture levels with a 24/7 system such as Smart Fog’s dry fog humidifier can prevent powdery mildew, bacterial growth, and electrostatic discharge (ESD) issues before they start. In this comprehensive guide, we’ll explore how around-the-clock humidity regulation enhances product quality, reduces downtime and energy costs, and creates safer, more efficient production environments for operations managers and facility engineers.

**Overview:** Proper humidity management offers numerous industrial humidifier benefits – from mold and mildew prevention to ESD prevention and improved air quality in manufacturing environments. Below, we break down the key advantages of Smart Fog’s 24/7 humidity control system and how it helps maintain optimal humidity levels (around 40–55% RH) in factories and warehouses. You’ll learn how stable humidity eliminates static, safeguards products and equipment, boosts efficiency, and even lowers energy usage. Let’s dive in.

Safeguarding Health & Hygiene: Preventing Mold, Mildew & Bacterial Growth

Excess humidity can foster mold and mildew, while too little humidity can allow dust and microbes to flourish. Smart Fog’s 24/7 humidity control system keeps conditions in the “Goldilocks zone” – not too damp and not too dry – virtually eliminating these contamination risks. In fact, the system’s precision control prevents any condensation on surfaces, so mold (including powdery mildew) never gets a chance to grow. By maintaining non-fluctuating humidity levels, Smart Fog eliminates the possibility of condensation, and thus mold and mildew issues, entirely.

Beyond mold prevention, the Smart Fog dry fog humidifier system actively sanitizes the air. Its ultra-fine 4.2-micron water droplets create a “clean fog” that attracts airborne particles like bacteria and viruses, oxidizing and neutralizing them in mid-air.

This means the system provides a bacteria-free, dust-free environment as a byproduct of humidity control. Unlike conventional humidifiers, which can sometimes breed bacteria in reservoirs, Smart Fog’s technology produces hygienic humidity with no standing water. The result is improved air quality in the manufacturing space and a healthier environment for products and personnel.

Consider the implications for industries like food processing, pharmaceuticals, or any operation where contamination is a concern. By preventing microbial growth and airborne pathogens, continuous humidity control protects product integrity and reduces the chance of costly recalls or health inspections issues. It also creates a safer workplace – employees are less likely to encounter musty odors, mold spores, or bacteria-laden air that could cause illness.

- Tip: Keep relative humidity around 45–50% RH to discourage mold (which tends to thrive above ~60% RH) while still reaping anti-static benefits. Smart Fog systems allow you to dial in these optimal humidity levels precisely 24/7.

- Action Item: Regularly monitor areas prone to moisture (e.g. near HVAC vents or cold spots) to ensure no condensation is forming. Smart Fog’s sensors and automated controls can assist by logging humidity data and alerting you to any deviations.

Eliminating Static & ESD: Protecting Equipment and Electronics

Dry air and static electricity are a dangerous duo in manufacturing. When humidity drops below roughly 40–45% RH, friction from machinery and material handling can build up static charges that discharge as sparks. These electrostatic discharges (ESD) can wreak havoc: igniting combustible dust or fumes, zapping sensitive electronics, causing packaging materials to misfeed, and even shocking workers. In fact, friction-induced static tends to occur when humidity is below 45% RH, but maintaining humidity above 55% RH ensures static will never build up. This is why ESD prevention is one of the biggest drivers for industrial humidity control.

Smart Fog’s humidity control system excels at eliminating static at the source. By continuously keeping the air moisturized to an optimal setpoint (often ~50% RH), it acts as a natural anti-static shield – water molecules in the air allow charges to dissipate harmlessly instead of building up. The difference is dramatic: even a modest increase from very dry conditions can nearly eliminate static sparks. For example, in electronics manufacturing, one facility found that implementing precise humidity control reduced static-related issues by 95% within the first month. They saw immediate benefits: fewer equipment malfunctions, less product scrap from ESD damage, and far fewer unexpected line stoppages.

By preventing static and ESD, you protect both your equipment and your output. Sensitive machinery like circuit board assemblers, packaging lines, and textile machines suffer fewer jams or errors. Electronics and semiconductor manufacturers, in particular, avoid costly damage to components – saving potentially hundreds of thousands of dollars in warranty claims and rework. But even in industries like printing, plastics, automotive, or powder processing, the benefits are tangible. Proper humidity removes the “invisible menace” of static cling that can cause materials to stick, clog, or misfeed. It also eliminates the shock hazard for staff (no one enjoys painful static zaps on the job) and minimizes fire/explosion risks from sparks in flammable environments.

- Tip: Set your Smart Fog system to maintain at least 40% RH across your production areas. According to industry guidelines, keeping humidity in the 40–60% range is ideal – it’s high enough to neutralize static but low enough to avoid condensation.

- Checkpoints: Monitor static-prone zones (e.g. near fast-moving conveyors, plastic film unwinders, or electronics assembly benches). With Smart Fog’s de-correlation technology, charged particles and dust are actively attracted and neutralized, but it’s still good practice to use ESD mats or grounding where necessary as redundant protection.

Real-World Impact – Static Control in Action

Even a single ESD event can have outsized consequences. One case study revealed that a sudden static discharge ruined an entire run of custom electronics, racking up $150,000 in scrap losses and 3 weeks of downtime for the manufacturer. The lesson was clear: investing in continuous humidity control is far cheaper than absorbing ESD disasters. After installing a Smart Fog precision humidification system, that same manufacturer cut warranty claims by over $100,000 per year and virtually eliminated unplanned downtime due to static. The system quickly paid for itself by keeping production on track and safeguarding product quality.

Enhancing Product Quality & Consistency

A stable humidity environment doesn’t just prevent problems – it actively improves the quality and consistency of your products. Many materials and processes are humidity-sensitive. For instance, in pharmaceutical tablet manufacturing, low humidity can cause tablets to crack or ingredients to separate, while high humidity can lead to clumping or delayed drying of coatings. In woodworking or furniture production, uncontrolled humidity might warp wood or cause finishes to cure improperly. And in precision electronics or optics, even slight humidity swings can impact calibration and yields.

Smart Fog’s 24/7 system eliminates these variability factors by keeping the indoor climate uniformly within spec at all times. Unlike standard HVAC humidifiers that may allow swings of ±10% RH, Smart Fog holds humidity to within about 1–2% of the target setting. This tight control means every shift, every day, products are made under the same optimal conditions. The payoff is higher yield and less waste. Manufacturers experience fewer defects like brittle materials, misalignments, or dimension changes caused by moisture fluctuations.

Optimal humidity levels also help maintain the properties of raw materials and components. Paper, textiles, wood, and plastics all respond to ambient moisture. For example, paper stored in a too-dry warehouse becomes prone to static and can curl or tear in printers, whereas paper stored at proper humidity stays flat and feeds smoothly. Similarly, in a warehouse humidity control context, keeping a storage facility at moderate humidity prevents products and packaging from drying out or absorbing too much moisture. Smart Fog systems are used in warehouses and storage rooms to protect inventory ranging from electronics to perishables. They preserve not just the products but also the equipment and even the building itself – preventing dry rot or corrosion that can occur when humidity swings wildly.

Ultimately, consistent humidity translates to consistent quality. Operations managers notice more uniform production results and fewer environmental-driven issues on the line. By eliminating one big source of variability, you can tighten quality control tolerances. Many Smart Fog clients report increased production yields and a reduction in rejects after implementing precise humidity regulation. When every product comes out right the first time, you save on rework, scrap, and customer returns – boosting both profitability and reputation.

- Quality Assurance Tip: Document the environmental conditions of your production (temperature and RH) alongside batch records. Smart Fog’s system can log humidity data 24/7 for audit and compliance purposes. This traceability helps prove that each product was made under the specified optimal conditions, which is valuable for ISO standards, FDA regulations, or internal QA audits.

- Long-Term Benefit: Over years, maintaining proper humidity can extend equipment life and calibration stability. Machines experience less wear from static shocks or thermal stress due to fluctuating humidity. Sensors and calibration devices remain accurate longer. All this means less frequent recalibration or part replacement, indirectly keeping quality high and maintenance costs low.

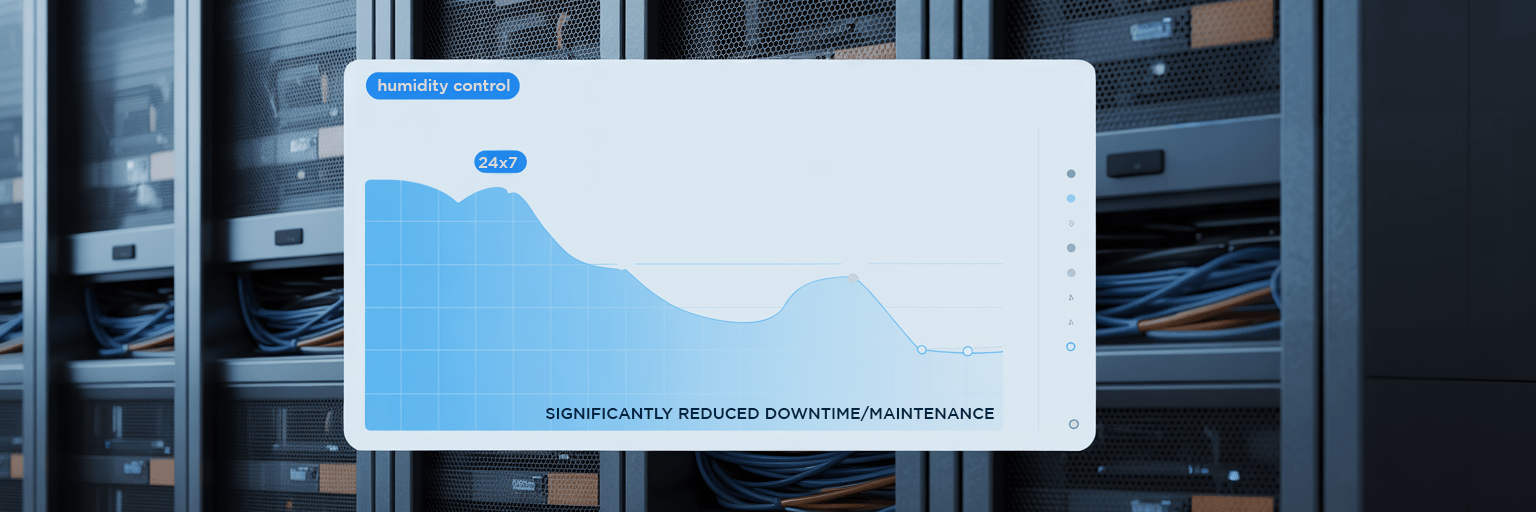

Reducing Downtime & Maintenance with 24/7 Control

Unplanned downtime is the bane of manufacturing – and improper humidity can be an insidious cause of it. Static-induced equipment crashes, jams from materials sticking, or cleanup stoppages due to mold or dust buildup are all examples of humidity-related downtime. National estimates put the cost of downtime in manufacturing as high as $260,000 per hour for some industries, once you factor in lost output and idle labor. Every minute counts.

A Smart Fog humidity control system significantly reduces downtime by preventing those humidity-related incidents from occurring in the first place. By eliminating static and keeping the environment dust-free, machines run more smoothly with fewer errors. There’s less need to pause production to clear jams or clean out debris. And because the system maintains a stable environment even during off-hours, you won’t come in on Monday to find rust or mold has formed over the weekend.

Maintenance requirements also drop with proper humidity control. For example, lubricated machines benefit from humidity – excessively dry air can cause lubricants to evaporate or thicken, whereas balanced humidity keeps them in better condition. Electronics and circuit boards in equipment aren’t subjected to static zaps, so they last longer without repairs. Moreover, Smart Fog’s “non-wetting” fog means no condensation inside HVAC ducts or on equipment, which eliminates the threat of corrosion or moisture damage in your facility. This all adds up to fewer emergency fixes and a longer lifespan for your assets.

One often overlooked benefit is that Smart Fog systems are themselves low-maintenance. They feature no moving parts in the core fogging mechanism and use automated controls, so there’s minimal upkeep compared to traditional humidifiers (which often require frequent cleaning of tanks, replacing pads, etc.). The Smart Fog ES100 units, for instance, are designed to run continuously with only periodic filter checks and little to no downtime for service. This means you get the advantages of humidity control without adding another maintenance burden on your team. In fact, many facilities find that the system effectively “runs in the background,” integrating with building automation and requiring far less attention than other HVAC equipment.

- Preventative Measure: Include humidity checks in your routine maintenance inspections. If levels strayed out of the optimal range due to an HVAC issue or extreme weather, address it proactively. But with Smart Fog’s 24/7 monitoring and control, such excursions are rare and brief – the system auto-corrects humidity within seconds to minutes, preventing minor issues from snowballing into downtime events.

- Takeaway: Every hour of uptime saved is money in the bank. By cutting static and moisture-related stoppages, facilities can run more reliably. Think of humidity control as an insurance policy against one of the most common invisible disruptors in manufacturing. It helps ensure you hit production targets without unexpected climate hiccups slowing you down.

Cutting Energy Costs with Efficient Humidity Management

In addition to protecting products and processes, Smart Fog’s humidity control solution is engineered for energy efficiency – which directly contributes to lower operating costs. Traditional humidification methods (like old steam humidifiers or high-pressure misters) can be notoriously energy-hungry, either by boiling water or by requiring powerful pumps. Smart Fog’s approach is different: it’s an adiabatic “dry fog” system that works with nature to add humidity using minimal energy input. The technology atomizes water into ultra-fine droplets at low pressure, achieving evaporation and cooling without heat. This results in dramatically lower energy consumption. In fact, Smart Fog systems use 50–90% less energy than other humidifiers on the market. Many customers see their humidity control energy costs cut in half (or better) after switching to Smart Fog.

The energy savings come not just from the humidifier itself, but also from side benefits of the process. Because the fog droplets absorb heat as they evaporate (adiabatic cooling), the system can provide a slight cooling effect to the space, easing the load on your air conditioning in warm seasons. Unlike steam systems that add heat and require more AC to compensate, a dry fog system is gentle on your HVAC. Additionally, maintaining proper humidity can make a given temperature feel more comfortable, potentially allowing you to set thermostats a bit higher in summer or lower in winter without sacrificing comfort – thereby saving additional energy on heating/cooling.

The efficiency doesn’t stop at energy; water usage is also optimized. Smart Fog achieves a 100% evaporation rate, meaning every drop of water is converted to humidity with no waste. There’s no dripping or draining needed. This is both a cost benefit and an environmental plus (especially in areas where water conservation matters).

All told, a humidity control upgrade can yield substantial ROI through energy savings alone. For example, one analysis found that modern precision humidifiers saved about $4,000 per year in energy costs for a mid-sized electronics plant, compared to their old humidification setup. Over a decade, that’s tens of thousands of dollars back in the budget. When combined with the reductions in scrap, rework, downtime, and maintenance we’ve discussed, the financial case for Smart Fog’s system becomes very compelling. It’s a rare win-win where you’re improving your process and cutting overhead at the same time.

- Energy Tip: If you’re currently using steam injection humidifiers or heating elements for humidity, consider the quick payback of switching to adiabatic dry fog. Smart Fog’s self-evaporative process can reduce energy consumption by up to 80% compared to steam systems}. That means lower utility bills and a greener footprint for your facility.

- Note: Smart Fog systems also support “eco-mode” operation, adjusting output to maintain setpoints without overshooting. This avoids needless energy use once optimal humidity is reached. Advanced controls and sensors ensure you’re only using as much water and power as necessary to maintain the target RH, no more and no less.

Frequently Asked Questions (FAQ)

Q. What is the optimal humidity level for manufacturing facilities?

Generally, keeping relative humidity around 45–55% is optimal for most manufacturing environments. This range is high enough to prevent static electricity (ESD prevention) and reduce dust, but low enough to avoid condensation and mold growth. Some industries have specific needs (for instance, electronics might target 40%+ to eliminate ESD, while woodworking might aim near 50% to prevent wood shrinkage). Smart Fog systems allow precise adjustment of humidity levels to meet your facility’s specific requirements, ensuring you stay in the ideal range for both product quality and safety.

Q. How does humidity control improve air quality in manufacturing?

A: Proper humidity control significantly improves air quality in manufacturing settings by suppressing airborne dust and contaminants. Moist air holds particulate matter down, so you’ll notice less dust floating around. In fact, Smart Fog’s droplets actively capture dust and even eliminate airborne bacteria and viruses by oxidizing them. This results in cleaner air for workers to breathe and reduces contaminants that could land on products. Additionally, optimal humidity keeps employees’ respiratory passages comfortable (no more scratchy throats and dry noses), potentially reducing illness and absenteeism. Overall, a humidified facility is a healthier and more pleasant place to work.

Q. Will using a humidifier make my factory wet or cause mold?

Not with a dry fog humidifier system like Smart Fog. These systems are specifically designed to humidify without wetting surfaces. The droplets are extremely fine (about 4 microns) and evaporate completely into the air. Smart Fog guarantees 100% evaporation, meaning no puddles, no condensation on walls or equipment, and no dripping from ducts. Because there’s no excess moisture accumulating, the risk of mold is actually eliminated – in contrast to poorly controlled environments where condensation can breed mold. Smart Fog’s technology was engineered to provide the benefits of humidity without the side effects of wetness. Many facilities that were once hesitant about humidification (fearing mold or rust) have successfully used Smart Fog for years with zero moisture damage.

Q. Can a humidity control system help with static in electronics manufacturing (ESD)?

Absolutely. In electronics and semiconductor manufacturing, maintaining humidity is a primary strategy for ESD prevention. Dry air makes static build-up very likely, which can silently damage electronic components. By keeping RH around 40-50%, you create an environment where static charges dissipate before they discharge. As mentioned earlier, companies have seen near-elimination of static problems after installing precision humidity control – with one reporting a 95% drop in static incidents and substantial savings in scrap costs. Smart Fog systems even have an ESD control function built-in (part of its “four functions in one”: humidity control, cooling, dust suppression, and static elimination. So yes, a humidity system is not just helpful but often essential for ESD-sensitive production.

Q. How does Smart Fog compare to traditional humidifiers in terms of maintenance and cost?

Smart Fog’s 24/7 humidity control systems are designed to be low-maintenance and cost-effective. Unlike traditional steam humidifiers that have heating elements (which can scale up or require frequent replacement) or mist systems with moving fan parts, Smart Fog uses a simplified, durable design with no moving parts in the nozzle unit. This means there are fewer components that can break or wear out. Maintenance mainly involves routine checks of water filters and occasional nozzle cleaning, which is relatively easy. In terms of cost, Smart Fog units might have an upfront investment, but they quickly pay off through energy savings (50–90% less energy use) and the prevention of downtime and product loss. Many facilities find the ROI is achieved in a matter of months to a couple of years, after which the continued benefits are essentially added profit. Plus, with Smart Fog’s long lifespan and robust build (high-grade stainless steel and plastic components, you won’t be frequently replacing the system – it’s built to last and serve your facility for the long haul.

Conclusion: A Smarter Environment for Better Manufacturing

Achieving the right humidity control in manufacturing facilities is not just about avoiding static shocks or keeping mold off the walls – it’s about creating an optimized environment where everything runs smoother. With Smart Fog’s 24/7 dry fog system, operations managers and facility engineers can virtually “set and forget” their humidity, knowing that a critical piece of the climate puzzle is handled with precision. The benefits ripple across your operations: no more powdery mildew or bacterial outbreaks threatening product safety, no more ESD fried electronics or jammed machines slowing you down, and no more excessive energy bills from outdated humidifiers.

In short, humidity control in manufacturing facilities using Smart Fog translates to consistent quality, increased uptime, and lower costs. It’s a proactive solution that addresses issues before they happen – preventing defects instead of fixing them, and maintaining stability instead of reacting to chaos. In an industry where margins are tight and reliability is everything, this kind of environmental control is a competitive advantage.

Don’t let an “invisible” factor like humidity undermine your hard work. By investing in a proven 24/7 humidity control system, you’re really investing in the longevity and efficiency of your entire operation. The evidence is clear in the facilities that have adopted it: higher yields, fewer accidents, healthier workers, and happier customers. It’s time to take control of your atmosphere. Ready to experience these benefits first-hand? See Smart Fog in action and consult with our experts to explore how precise humidity control can transform your manufacturing environment.